Saïs Report, 2009

Season Reports

Saïs Report, 20092.

Pottery from the Village Waste-Water Project

The main aim of the study seasons was to create an efficient and reliable system for dealing with the large amounts of pottery collected as a result of the Waste Water and Sewage Project in the village of Sa el-Hagar. A system was developed by Nathalie Andrews of Durham University and comprised a sorting system where material could be quickly assessed and recorded and then a basic typology could be created. Subsequently, when finds are compared with the typology, they can be allocated a number based on the types already described, so that the amount of material needing to be drawn would be reduced. With the two systems in place, it should be possible to sort through large collections of pottery relatively quickly, without having to draw every diagnostic sherd.

Pottery stored in the magazine. All of the material on the right has been processed and recorded. Work on the pottery in the baskets and sacks on the left was begun in 2009.

Having developed recording sheets in the spring, a team consisting of Natalie Proctor, Marwa Ahmed-Mohammed, Louise Brown and Hajah nur Kamilah bint Ismail, all of Durham University, implemented the system in the summer. The short trial period enabled us to clear 10 sets of pottery baskets. The material was sorted into pottery fabric types and stones. The stones were kept for drawing if they were worked or interesting in other ways. The diagnostic pieces of pottery were numbered and then all of the sherds were recorded on the recording sheets. These sheets will eventually be added to a spreadsheet-database in order to sort and analyse the data carefully. A number of the diagnostic pottery sherds were drawn in order to create a typology for the material.

It seems from the material from the street bordering the western side of the Great Pit, that there is a mixture of dates of material. There were a number of Saite period Nile silt vessels as well as imported Greek amphorae fragments. There was also material from Ptolemaic and Roman periods, including the Amphore Égyptienne Type 3 amphorae. The dates of the material seemed to suggest that the western side of the ‘Great Pit’ was in continuous occupation from the Saite period through into the Roman period, similar to the situation on the eastern side of the Pit. It may have been the case that the rubbish dumps from the Saite city provided a good location for the industrial areas of the large Ptolemaic and Roman settlement at the site.

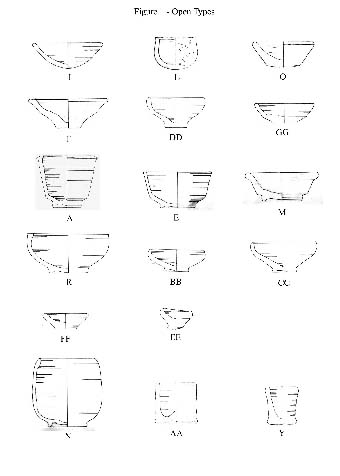

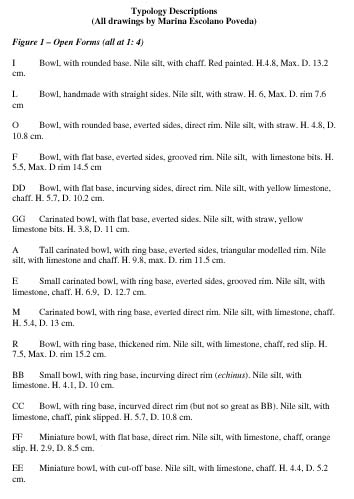

The work also focussed on a find of pottery, made during the waster water project and monitored and collected by the SCA Inspectors at the site. The monitoring team reported that the pottery came from a kiln site to the north of the tomb of Sidia Saba. Many vessels from here were found broken, but it was possible to reconstruct some of them. The assemblage proved to be an interesting mixture of locally produced Nile Silt tablewares, as well as more functional types of vessels, such as flat-based, straight-sided, small ‘bread moulds’. There were some imitation foreign vessels, such as spindle bottles and small squat jars, painted with brown-purple bands. In addition, there were miniature bowls and offering pots and some Bes jars. There were also wasters from the kiln. The importance of the kiln is that it shows the range and amount of material that could be produced from one kiln. Most of the pieces from this particular find were of a small size, no more than 12.5 cm in height. It is likely that they were intended to be a batch of locally produced fine and tablewares for the home market, with a few more functional vessels included (Figures 1 and 2).

Fig. 1 : Ptolemaic pot types.

Click image to view at full-size. (Requires PDF Viewer browser plug-in.)

Fig. 2 : Descriptions of the pottery.

Click image to view PDF document.

(Requires PDF Viewer browser plug-in.)

Right : Imitation Rhodian amphora G. Height 14.1 cm.

The materials for the vessels were all Nile silt but they varied in their fineness and inclusions to a degree, reflecting the precise function of the vessel. The jugs, for example, were all of fine, well levigated clay (soaked to remove all impurities), whereas the small bowls were of coarser clay with much chaff and straw added to the mixture. Such variations will provide information about the way in which different batches of clay were prepared for specific types of vessel. Some vessels were also meant to imitate marls clays with the addition of a cream or white wash to the outside – although in the case of one jug, something had happened during the firing process and the jug had crumpled. It will also be interesting to compare the pottery with that from the kilns recently studied at Buto, in order to look at these two regional production centres and compare their individual corpuses. This may show very localised tastes as well as more general fashions in fine tableware.

Left : Jug D. Height 14cm. Right: Misfired jug JJ. Height 13.7 cm.

Next : Survey work